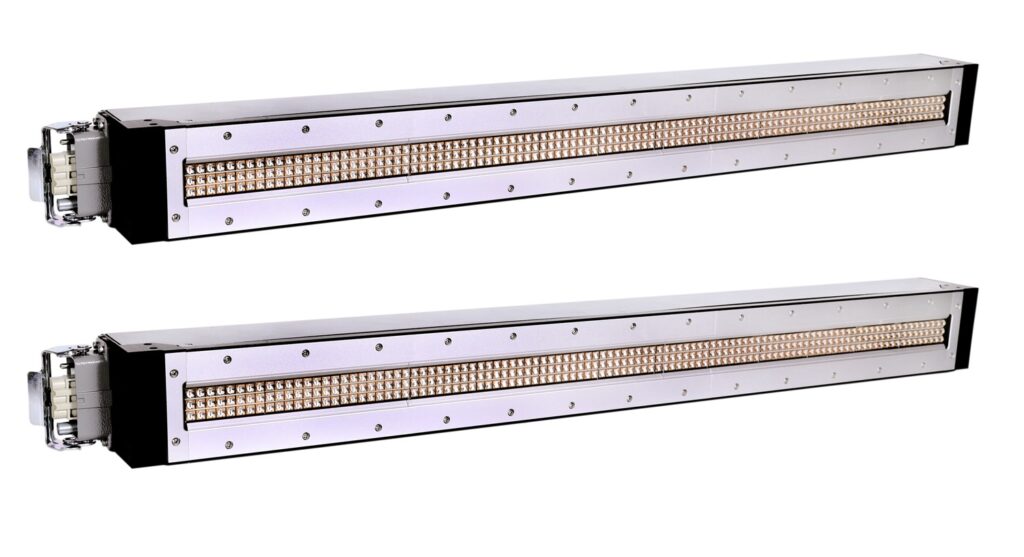

HPE (High Power Equipment) LED UV System.

HPE LED UV SYSTEM

HPE (High Power Equipment) LED UV System

The HPE (High Power Equipment) LED UV system represents a cutting-edge technology in UV curing, widely used in Printing, Coating, and various other industrial applications. UV curing employs ultraviolet light to quickly and efficiently dry or cure Inks, Coatings, Adhesives, and other materials.

This system utilizes High-power LEDs to generate the UV light necessary for the curing process. The applications of HPE LED UV technology are diverse, including Curing, Sterilization, Coating, Printing, and Adhesive bonding.

Key benefits of HPE LED UV technology include its energy efficiency, extended lifespan, and reduced maintenance requirements. These advantages make it a more sustainable and cost-effective solution compared to traditional UV curing methods.

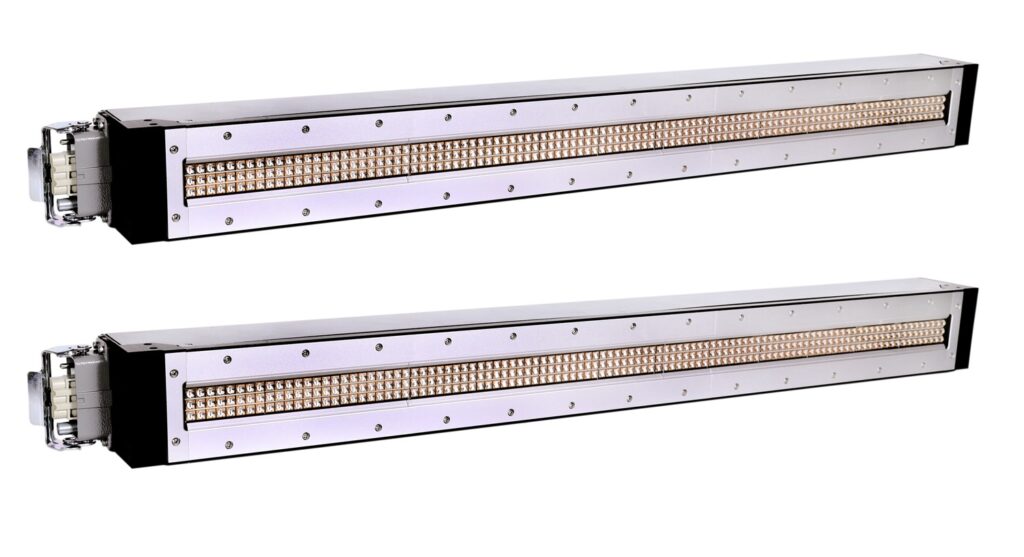

FEATURES OF HPE LED UV CURING SYSTEM ARE:

- One power supply can drive both normal UV lamps and LED UV hoods.

- Easy installation with minimal cabling, reducing failure rates.

- Single power supply drives LEDs, maintaining equal current for each chip.

- Real-time feedback and continuous control of LED hood voltage and current.

- Cooling system designed using finite element analysis for optimal LED performance at low temperatures.

- Multiple protection circuits ensure system stability.

- Common power supply for LED and UV HPE systems.

- LED and UV HPE systems are made by HPE, ensuring quality and compatibility.

- Power consumption: 7 kW per unit, making it energy-efficient and cost-effective.

- HPE UV system can process 10,000 sheets per hour, making it a high-speed and productive solution.

- 2TR Chiller (SS body, three-phase) with tank on top and electronic water flow switch.

- HPE UV system includes an electronic water flow switch, which monitors and controls the water flow, ensuring optimal cooling and preventing damage.

- Quick-release coupler for easy connection and disconnection of lines.

- Warranty: 1-year coverage for manufacturing defects only.

APPLICATIONS OF HPE LED UV CURING SYSTEM ARE

PRINTING

- UV curing inks in Digital printing

- UV curing inks in Screen printing

- UV curing inks in Offset printing

COATINGS

- Curing protective coatings

- Curing decorative coatings

ADHESIVES

- Fast curing of adhesives in assembly processes

- Fast curing of adhesives in bonding processes

ELECTRONICS

- Curing coatings in electronic device manufacturing

- Curing encapsulants in electronic device manufacturing

MEDICAL DEVICES

Curing bio compatible materials in medical device manufacturing

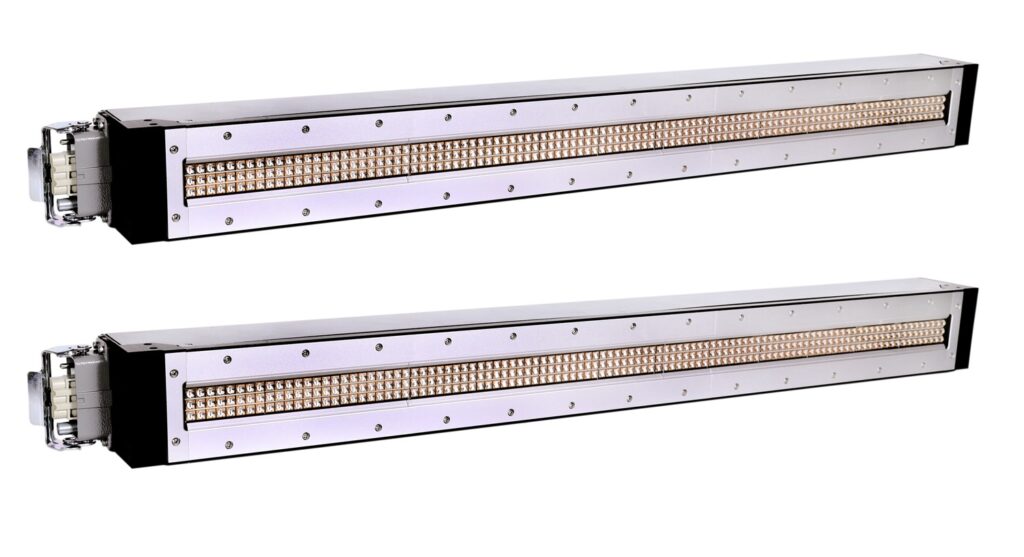

ADVANTAGES OF HPE LED UV CURING SYSTEM ARE:

- High power output for the fastest and more efficient curing process.

- Reduced energy consumption, resulting in lower operational costs.

- Extended operational life due to optimized design and higher efficiency.

- Instant on/off Capability without any warm-up period, enhancing operational efficiency and productivity.

- Provides uniform and consistent curing results, ensuring high-quality finishes and strong adhesion properties.

- High-speed curing, increasing overall production speed.

- Reduced maintenance with fewer consumable parts and less frequent replacements.

- Enhanced Safety due to minimal heat generation, reducing the risk of burns or thermal damage during operation.

- Suitable for a variety of industrial applications, including Printing, Coatings, Adhesives, Medical device manufacturing, Automotive, Electronics and Packaging.

COMPARISON BETWEEN HPE LED UV CURING AND LED UV CURING SYSTEM:

HIGH POWER AND INTENSITY:

- HPE LED UV systems are designed to deliver significantly higher power and intensity for various industrial applications that require rapid and deep curing. In contrast, Standard LED UV curing systems provide effective curing but have limitations in terms of power and intensity compared to HPE systems.

ENERGY EFFICIENCY:

- HPE LED UV systems are optimized for maximum energy efficiency, reducing power consumption and operational costs, resulting in cost savings and less environmental impact. Standard LED UV curing systems, on the other hand, may not achieve the same level of energy efficiency as HPE systems and have moderate operational costs.

HEAT GENERATION:

- HPE LED UV systems generate less heat compared to standard LED UV curing systems, reducing the need for extensive cooling and enabling the curing of heat-sensitive materials. While Standard LED UV Curing Systems produce less heat than traditional UV lamps, they still produce more heat than HPE systems and require cooling mechanisms.

EXTENDED OPERATIONAL LIFE:

- HPE LED UV systems offer a longer operational life due to their optimized design and higher efficiency, reducing the need for frequent replacements and maintenance. Standard LED UV curing systems also have a long lifespan but require periodic maintenance and replacement, whereas HPE systems often last longer.

ENVIRONMENTAL BENEFITS

- HPE LED UV system does not contain hazardous materials like Mercury and produces very little ozone, resulting in a lower environmental impact. Additionally, it emits less heat, reducing the risk of substrate damage and providing a more comfortable working environment. In contrast, standard LED UV curing systems are also mercury-free and environmentally friendly but have a moderate environmental impact compared to the HPE LED UV curing system.

In nutshell, HPE LED UV technology offers a more sustainable, high-performance, efficient, costeffective, environmental friendly and versatile solution for UV curing applications in various industries.