Powerful Interdeck UV system and UV Coating System for Printing industry.

INTERDECK UV SYSTEM

PRINT WITH IMPACT, CONSUME WITH EFFICIENCY

When it comes to Interdeck system manufacturers, the best fit depends on specific requirements, such as printing press type, substrates, budget, and desired print quality. However, SASG stands out as a leading player in the UV system printing industry, and here’s why:

Unmatched Reputation: With decades of expertise in UV Coating systems, SASG is renowned for its cutting-edge UV technology.

Comprehensive Product Range: SASG offers a wide range of UV systems for printing industry, including traditional UV lamp systems and innovative LED UV systems.

Innovation Leader: SASG continuously pushes the boundaries of UV technology, developing energy-efficient and high-performance UV Interdeck solutions.

Customized Solutions: SASG provides tailored UV coating equipment to meet specific needs, ensuring seamless integration with various printing presses.

Interdeck UV Systems are designed to improve print quality, speed up production, and offer flexibility in the types of materials that can be printed on.

AIR COOL INTERDECK SYSTEM

- Instant ink curing rapidly cures UV-sensitive inks and coatings enabling high speed printing.

- Enhanced print quality delivers sharper images and more vibrant colors with fewer imperfections.

- Versatility supports printing on a wide range of substrates, including nonporous materials like plastics and metals.

- Reduced installation time and increases throughput with immediate curing capabilities.

- Energy efficiency lowers power consumption and eliminates the need for water-cooling infrastructure.

- Compact design easily integrates into existing printing presses.

- Environmental benefits provide a solvent-free process that reduces VOC emissions and lessens environmental impact.

These applications make Air-cooled Interdeck UV systems a versatile and valuable tool in modern printing environments.

WATER COOL INTERDECK SYSTEM

- Higher power output sustains higher UV lamp intensities without overheating.

- Better for high-speed printing handles, higher power outputs for rapid curing.

- Handling heat-sensitive substrates maintains a stable temperature for printing on heat-sensitive substrates.

- Enhanced durability and lifespan of UV lamps extends the lifespan of UV lamps through effective temperature management.

- Consistent performance provides uniform curing and improved print quality through consistent thermal management.

- Reduced maintenance needs require less frequent cleaning and maintenance of cooling components.

- Suitable for high-speed web offset printing sheefted on paper, plastics, and other materials.

- Ideal for printing on heat-sensitive substrates that cannot withstand higher temperatures.

- Compatible with thicker coatings and special inks that require more powerful curing.

- Increased productivity enables faster production and higher volume printing capabilities.

SAFETY & SECURITY MEASURES

SAFETY

- Temperature sensor monitors UV lamp temperature for safety.

- Blower safety ensures proper airflow and cooling.

- Chiller safety regulates cooling water temperature.

- Shutter safety protects operators from UV radiation.

- Complete panel safety encloses electrical & mechanical components.

- Install smoke or heat detectors near the UV system.

SECURITIES

- Follow a regular maintenance schedule.

- Familiarize operators with emergency stops.

- Install smoke or heat detectors near the UV system.

- Handling UV lamps ensures safe handling and disposal.

- Monitor temperature regularly.

- Inspect electrical components regularly.

- Keep covers and shields in place during operation.

- Use UV-rated safety glasses or face shields.

FEATURES OF INTERDECK UV SYSTEMS ARE:

- Auto shutters: Protected by safety shutters

- Instant Curing: Rapid production speeds with instant curing.

- Enhanced Quality & Efficiency: Boost quality, reduce energy.

- Cost-Effective: Minimize costs & energy expenses

- Advanced Cooling Systems: Optimal performance with air/water cooling.

- Consistent Print Quality: Uniform results, precise control.

- Versatile Ink Compatibility: Wide range of ink options.

- Compact & Modular Design: Space-saving, easy integration.

- Intelligent Control Systems: Precise monitoring, control.

- High Durability & Reliability: Robust, reliable UV systems.

- Integrated Control Systems: Seamless system integration.

- Long-Lasting Lamps/LED’s: Extended lifespan, reduced maintenance.

- Eco-Friendly Operation: Environmentally responsible printingAuto shutters: Protected by safety shutters

- Instant Curing: Rapid production speeds with instant curing.

- Enhanced Quality & Efficiency: Boost quality, reduce energy.

- Cost-Effective: Minimize costs & energy expenses

- Advanced Cooling Systems: Optimal performance with air/water cooling.

- Consistent Print Quality: Uniform results, precise control.

- Versatile Ink Compatibility: Wide range of ink options.

- Compact & Modular Design: Space-saving, easy integration.

- Intelligent Control Systems: Precise monitoring, control.

- High Durability & Reliability: Robust, reliable UV systems.

- Integrated Control Systems: Seamless system integration.

- Long-Lasting Lamps/LED’s: Extended lifespan, reduced maintenance.

- Eco-Friendly Operation: Environmentally responsible printing

Mercury cure INTERDECK, (ANILOX COATING DRYER with UV DRIPOFF SYSTEM)

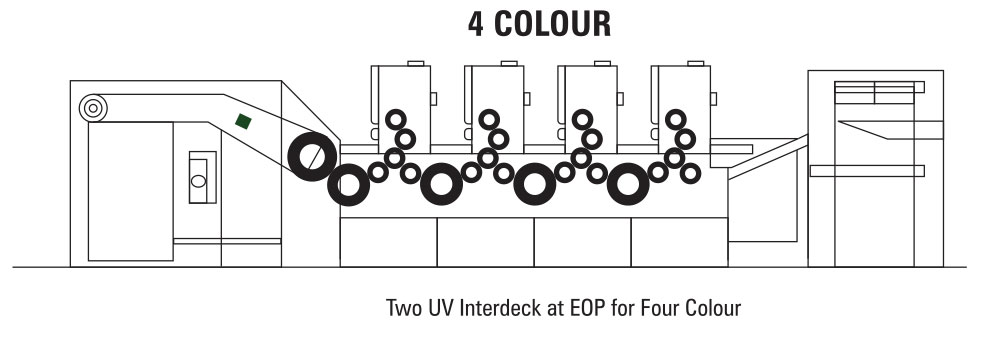

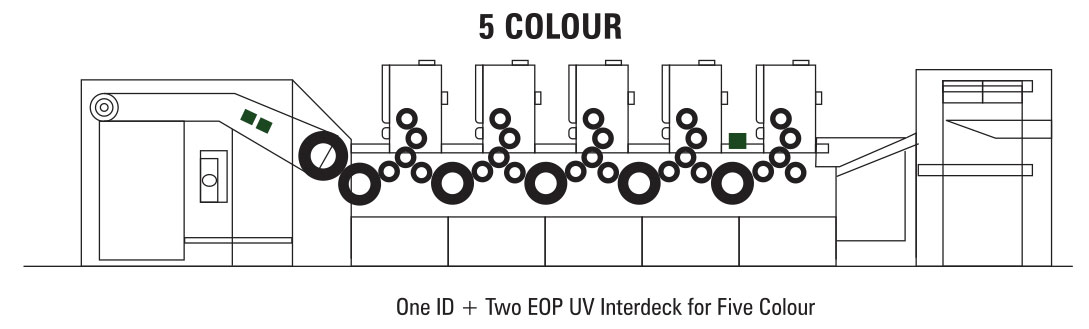

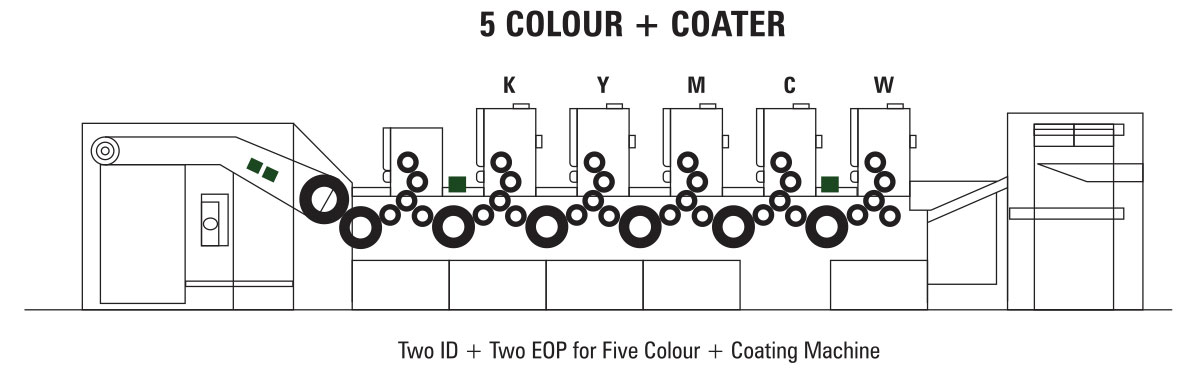

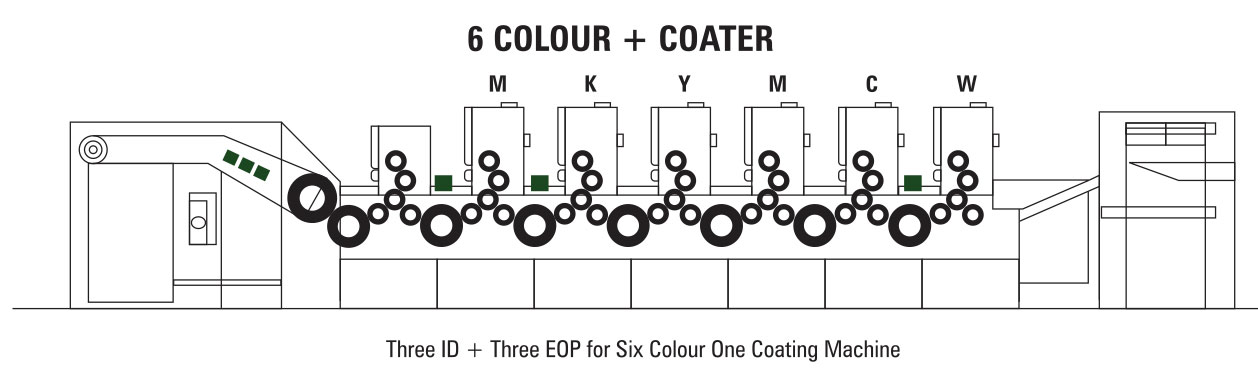

HOW INTERDECK WORKS?