Efficient LED UV Curing Technology for Coating Industries.

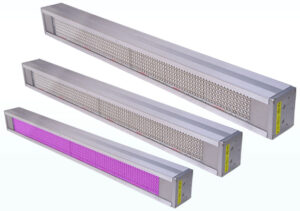

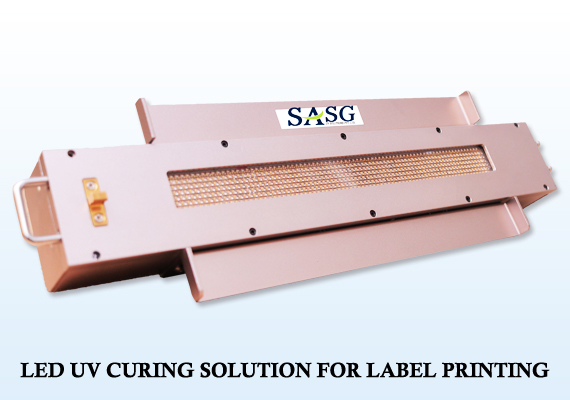

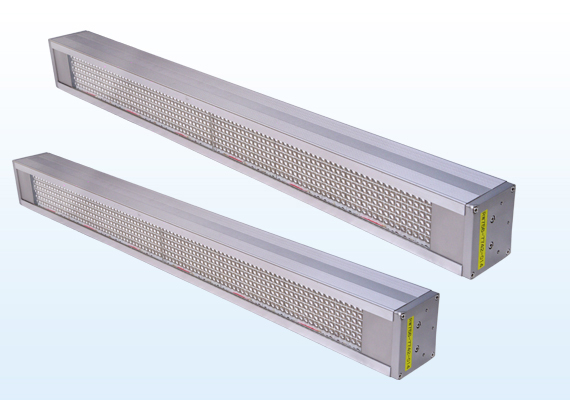

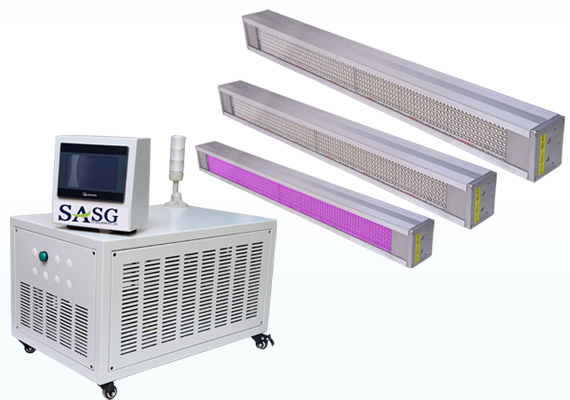

LED UV CURING SYSTEM

CONSISTENT COATING COMES FROM CONFIDENT CURING

Cutting-edge LED UV Curing System for Printing utilizes UV LED Curing System technology to deliver precise curing results. Led UV System ensures efficient drying and finishing, making it a popular choice for various industries. Led UV Curing System Manufacturers design these systems to meet specific application needs.

UV LED Curing technology is revolutionizing the coating industry by providing several advantages over conventional curing methods. Capable of curing materials containing photo initiators, LED UV systems excel in applications such as adhesive bonding, sealing, and drying materials like inks, lacquers, paints, and clear coats. Characterized by UV light, this process enables photo polymerization or radiation curing.

WHAT IS LED UV CURING

LED UV systems are used for materials that contain photo initiators, for example in applications for curing adhesives in bonding or sealing processes or for drying materials such as inks, lacquers, paints, and clear coats. Especially UV light, leads to photo polymerization or radiation curing.

FEATURES OF LED UV SYSTEM

- Convenient Installation: Led UV Curing machine offers convenient installation and operation.

- Compact Design: It has a Space-saving architecture for maximum productivity.

- Color Compatibility: Single LED Cassette required for 4-color printing.

- Compatible with All Presses: Seamless integration with various printing presses.

- Consistent Performance: UV LED Curing machine provides consistent performance and long-lasting diodes with a 25,000-hour lifespan.

- Cost-Effective: UV Curing system offers cost-effective and eco-friendly operation by achieving up to 80% power savings.

- Cool Running: Generating minimal heat, unlike conventional UV systems and it is safe and one of the efficient curing.

- Precise Wavelength: Emitting UV light at a specific 365-395nm wavelength.

- High quality Intuitive Operation: UV Curing System manufacturer ensures high-quality system design and build and it has a user-friendly single-touch operating system.

APPLICATIONS OF LED UV CURING SYSTEM

LED UV Curing machine widely used in various industries for enhancing product quality and production efficiency, mentioned below are the applications of LED UV system such as:

- Printing Industry- LED UV system used in various printing processes to rapidly cure inks, coatings, and adhesives, resulting in faster production speeds and higher quality prints.

- Packaging Industry- UV curing system cures inks and coatings on packaging materials, improving durability and appearance while maintaining food safety.

- Rubber Industry- UV LED curing used to cure coatings, adhesives, and inks on rubber products, improving durability and performance.

- Electronics Industry-UV LED curing machine used for curing conformal coatings, encapsulants, and adhesives in electronic component assembly, ensuring reliable performance and durability.

- Medical/Pharma Industry-LED UV systems used to cure coatings, adhesives, and inks on medical devices, ensuring secure bonding and meeting medical standards. Additionally, used for fungi sterilization and disinfection of medical instruments and equipment.

- Automobile Industry-UV curing system applied to cure coatings and adhesives on automotive parts, enhancing durability and appearance.

- Wood & Floor paint industry- LED UV system cures coatings and varnishes on wood products, providing a durable and attractive finish.

ADVANTAGES OF LED UV CURING MACHINE

- Environmentally friendly- LED UV curing systems offer several environmental benefits, including improved drying times, lower carbon emissions, and the absence of mercury or other hazardous materials.

- Gives consistent print quality and performance- UV LED curing systems provide consistent print quality and precise curing performance.

- Compatible with special media- UV LED curing systems are compatible with a wide range of special media, including plastics, metals, and other materials.

- Cost savings – LED UV curing systems reduce operational costs by consuming less energy and requiring less maintenance.

- Compact design- The smaller and lighter design of LED UV systems allows for easier integration into various manufacturing processes and equipment.

- Versatile Applications- UV LED curing systems are compatible with various applications, including printing, coatings, adhesives, paper, plastic, metal, and electronics.

- Faster curing times – UV LED curing systems cure ink instantly, allowing for faster printing speeds and increased productivity.

WHY LED?

General Features

- Basics of Systems

- Power Consumption

- SASG LED Life Time

- Temperature during operation

- Type of Source

- Environmental/health issues

- Maintenance Required

- Quality of Printing

LED UV

- Silicon Emitting Diode LED

- Low normally quantified hundreds of Watts/hr

- More than 25000, working hrs hours.It depends on the condition of use and the environment.

- 600 max. measured in lamp emitting window

- Monochromatic source for UV-a rays only

- No Mercury and other dangerous substances environment.

- No Mercury and other dangerous substances environment.

- Printing quality more constant

Mercury UV

- Fragile cylindrical quartz bulbs

- High normally quantified thousand of Watts/hr.

- Varying from 500 to 2,000 working No technical maintenance.

- Greater than 13500C on lamp window.The bulb can reach 9000C after a few minutes of operating.

- Rays emitted UV-A+UV-B+UV-c

- Contains mercury and metal halite potentially dangerous for the health.

- Frequent ordinary maintenance glass and production downtime

- Electromagnetic system containing transformers, Chokes, capacitors and igniter.

Advantages of LED

- High resistance to vibration and shock

- Power consumption is 70% less:thus investment cost is recovers by the user in a short time

- No UV emitter to replace.

- LED is instant ON/OFF there for save ample energy over mercury UV System

- Improved safety for the operation.It does not emit dangerous UV-C radiation

- It is not necessary to dispose emitter as special waste.

- Almost zero maintenance cost

- LED lamps is more compact and reliable over time/speed.